Supply chain management and the value chain #

The interlinking of several processes along the value chain of a product is very complex. From the procurement of the required goods, through production and warehousing, to delivery to the customer, processes must be efficiently planned, documented and monitored. This is the only way for companies to ensure that their production does not come to a standstill and that the customer receives the desired product at the right time – namely when they need it.

The task of a supply chain manager is to design and monitor these processes correctly. And thanks to modern software solutions, you now have ideal options for optimally mapping your Supply Chain Management (SCM). This means you always have your entire value chain under control.

In this blog article, you can find out more about SCM and how you can use digital transformation to optimize your material requirements planning, production and shipping.

What is supply chain management anyway? #

Generally speaking, supply chain management is all about planning, controlling and integrating all activities along the value chain of one or more products. This normally starts with the raw material supplier and ends with your customer. A supply chain manager is responsible for the integrated, process-oriented planning and control of all flows of goods, information and money.

- Material flow: The material flow deals with the actual transportation of the goods and includes the route from the raw material supplier via the central warehouse to the end customer and, if necessary, the return of the goods.

- Information flow: All relevant information about orders and their deliveries is transferred here. This means that all information, whether from external (partners) or internal (departments), flows together centrally in one place. This enables faster and more efficient decisions to be made in the event of delivery problems, for example.

- Financial flow: The financial flow includes credit terms, payment plans, as well as goods shipments and ownership.

What is the difference between supply chain management and logistics? #

Logistics and supply chain management are often used interchangeably. However, SCM actually goes far beyond pure logistics processes and encompasses all processes along the supply chain. Pure logistics, on the other hand, is primarily concerned with the physical transportation and storage of goods.

The importance of supply chain management for companies #

Supply chain management is crucial to the success of a company. With planned and executed processes in procurement , production and sales, efficient logistics and a stable supply chain, several goals can be achieved. The aim is always to ensure smooth logistics and reduce delays or disruptions to a minimum so that the entire value chain can function optimally.

- Reduce costs: Optimized resource planning and reliable suppliers reduce costs in the long term. This includes the rapid reduction of inventories, lowering storage costs, ensuring timely delivery (just-in-time supply) and shortening cash-to-cash cycles.

- Greater flexibility: Value chains and processes can be designed with efficient supply chain management so that you can react to changing market conditions and supply bottlenecks at short notice.

- Customer and supplier loyalty: Optimized processes and the ability to react quickly maintain and strengthen relationships with customers and suppliers. This increases delivery reliability.

- Efficiency gains: Workflows and processes are continuously reviewed and improved.

- Exchange of information: The tasks of supply chain management also include ensuring a smooth exchange of information so that the employees and external service providers involved receive relevant information promptly.

The 5 processes of the supply chain in supply chain management #

Supply chain managers in companies usually have to keep an eye on five processes that affect different departments. These are planning, procurement, production, distribution and returns.

- Planning: The actual suppliers play a major role here. It is important to identify suitable suppliers and to design a flexible and, above all, fast procurement process. The company’s own corporate policy is also a focus when selecting suppliers. The products and suppliers should match the company’s own quality requirements and values.

- Procurement area: The aim is to ensure an optimal supply for your own company. Of course, you should always act economically and keep procurement and warehousing costs as low as possible. Efficient and permanent material replenishment and an optimal storage concept are the top priority.

- Production area: In this area, all production processes are analyzed and optimized in detail. The focus here is on the resources of materials, production facilities and tools. Packaging concepts and employee qualification are also part of this area.

- Distribution: Employees in this area take care of the required means of transport, their capacity and utilization and optimized transport routes in order to reduce overall costs.

- Returns: Customers who are dissatisfied with a product or have received a damaged shipment want to be able to return their delivery as easily as possible and receive compensation. This step is often neglected in SCM, but is extremely important in order to increase customer satisfaction and thus customer loyalty.

Supply chain management in real time thanks to modern technologies #

Supply chain managers can benefit enormously from modern technologies in their work. Thanks to real-time information, order and delivery statuses are updated automatically. Automated notifications allow you to react promptly in the event of delays. Inventory management, demand forecasting, communication and collaboration within the company or data analysis: there is hardly an area in SCM where the digital transformation is not setting new standards. Responsible employees become faster and more agile as a result and can develop more efficient processes.

A modern SCM is based on systems that enable data collection, analysis and decision-making in real time. This allows reliable forecasts to be created and adapted directly to changing conditions, making disruptions more predictable. This enables companies to prepare and initiate appropriate measures at an early stage.

Supply chain management in a cloud environment #

Modern cloud environments enable more flexible supply chain management. In addition to the advantages already mentioned – speed, process automation, real-time communication – company growth can be easily scaled with a cloud solution. You only activate additional resources or functions when they are needed. Companies thus minimize their financial risk and reduce costs.

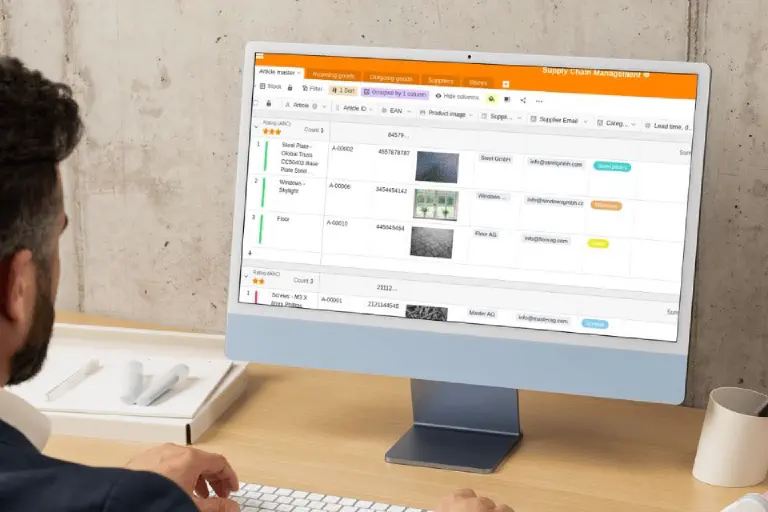

Cloud solutions such as the SeaTable no-code platform offer another advantage that should not be underestimated: they are not standardized, off-the-shelf solutions. On the contrary, supply chain managers can adapt the system to their specific requirements – either from scratch or using a supply chain management template as a basis.

The embedded template is scrollable and clickable.

5 tips for successful supply chain management #

Developing and managing efficient and effective supply chain management for your company is undoubtedly a challenging task. Modern technologies support you in setting up efficient processes and automating tasks. To ensure that your SCM really leads to optimal results, you should follow these five tips:

- Work collaboratively: We have already shown that modern SCM involves various cross-departmental areas. Involve all affected employees in the processes and promote a cooperative and collaborative working atmosphere in order to develop the best solutions together.

- Communicate regularly: Actively and openly share relevant information with affected colleagues and departments. This allows you to react more quickly to problems and identify weak points in your processes.

- Determine who is responsible: Define clear responsibilities for the individual process steps within your value chain from the outset. Many difficulties can be avoided if everyone involved knows who has to take action or make a decision and when.

- Optimize continuously: Process optimization is an ongoing task. Define a repetitive workflow for this, e.g. the PDCA cycle. In this circular concept, the four steps Plan, Do, Check and Act are constantly repeated. This makes your processes increasingly efficient and gives your company a competitive advantage

- Choose the right software: Communication, process visualization, automation of tasks, monitoring and reporting, supplier management – the list of tasks that a supply chain management platform must cover is long. Analyze your needs and the offerings on the market carefully. An often overlooked alternative to SCM software or work management platforms are no-code solutions such as SeaTable. These allow you to store all information and processes centrally and accessible to all parties involved and to adapt the structure to your specific needs.

Start the transformation of your supply chain management #

You now know what SCM is and what is important when it comes to optimization. The decisive step now is to create the technical framework. SeaTable creates a place where all information can come together. This allows you to efficiently map your supply chain management in just a few steps and clicks. Record all the necessary information, such as your suppliers, incoming and outgoing shipments and your product portfolio, and keep an eye on your entire warehouse. Collaborate with your colleagues in real time, set up automations for notifications or task assignments and use dashboards and statistics for data-based decisions. Simply register for free and test our supply chain management template.

FAQ Supply Chain Management #

What is supply chain management

What are the benefits of cloud-based SCM systems?

What are the three levels of supply chain management?

In a supply chain management strategy, a distinction is made between the operational, tactical and strategic levels. These differ in their temporal orientation.

- operational supply chain management: All decisions can be implemented at short notice or within days or a few weeks. Normally, this concerns processes that can be implemented quickly, such as process planning, loading or order processing. Relationships between orders and stocks are also analyzed. The aim here is to achieve the highest possible level of customer satisfaction, as the main focus is on customer relationships.

- tactical supply chain management: All decisions can be implemented in the medium term or between a quarter and a year. These relate, for example, to decisions regarding production quantities, production resources, inventories, shipping strategies and transportation.

- strategic supply chain management: Here, decisions are made with long-term success. These include, for example, the choice of location for the company’s own warehouse, production and storage capacities, investments, supplier selection, make-or-buy decisions and sales strategies.

TAGS: Procurement & Logistics